How does a Torque Converter work on a Go-Kart?

Trying to understand how these things work? That’s a good starting point to make any modification, if you’re looking to get the maximum performance out of your Torque converter then you’ll need to know how it works.

The torque converter uses a CVT (Continuously Variable Transmission) system, similar to the ones in scooters. But not exactly like the CVT from a scooter. It consists of 2 pulleys and a belt. A driver pulley (connected to the engine crankshaft), and a driven pulley along with a v-shaped belt.

Both the driven pulley and the driver pulley are further dived into 2 parts, one fixed part, and one moving part.

The belt goes in between the two pulleys, and initially, the belt in the driven pulley has a bigger diameter than the driver pulley.

As the RPM of the engine increases, the movable half of the driver pulley slides inwards (towards the engine), pushing the belt upward while simultaneously the driven pulley’s movable part moves outwards (away from the fixed part) and the belt slides down the driven pulley.

If you have ever seen a torque converter in action, you would have seen how the gear ratio changes, if not then you can watch a video for better understanding.

For this article, we will take a look inside the pulleys to figure out what exactly is going on and how these movable parts are moving as the RPM increases.

Parts:

Let’s first have a look at all the parts of the comet 30 series from their user manual. (The 40 series also works on a similar principle, the major difference is the weights and the spring inside the clutch of the driver pulley)

For our purpose of understanding how it all works, we will not be focusing on the nuts and bolts and washers, etc, only the label numbers 4-10 and 15-19 are important for us to understand the working mechanism.

Let’s first name all these important parts:

| Label # in the diagram | Item name and description |

| 4 | Drum of Driver |

| 5 | Hub of Driver |

| 6 | Weight and spring |

| 7 | Movable half |

| 9 | Belt |

| 10 | The stationary part of the driver |

| 15 | Cam fixed (the part that will hold the spring) |

| 16 | Spring of the driven pulley |

| 17 | Movable part |

| 19 | Fixed face |

How it works?

Now with the basic understanding of what happens as the throttle opens and with all the parts described, let’s look into how it works.

When you turn on the engine, the crankshaft will start to rotate, since the crankshaft is connected with the driver pulley, the weight-spring system of the driver pulley will rotate along with the crankshaft.

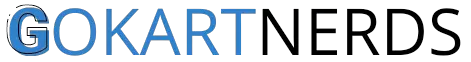

The most important part of the whole driver pulley system is this weight-spring system.

As the system starts to rotate, the weight will experience a centrifugal force in the direction opposite to the spring force, as the rpm increases the centrifugal force will also increase and pushes the weights in the outwards direction, and stretches the spring in the process. The spring will respond with an even higher force to resist this expansion.

If you take a look at part #7 in the diagram (the movable part of the driver), it is not flat but rather has some angle to it. So when this weight is expanding against the hub, it will start to come in contact with the movable half (part #7), pushing the movable half towards the engine.

The belt too has an angle according to the angle of the movable part, so when the movable part is pushed outwards, the belt adjusts itself, and the diameter of the belt in contact with the driver increases.

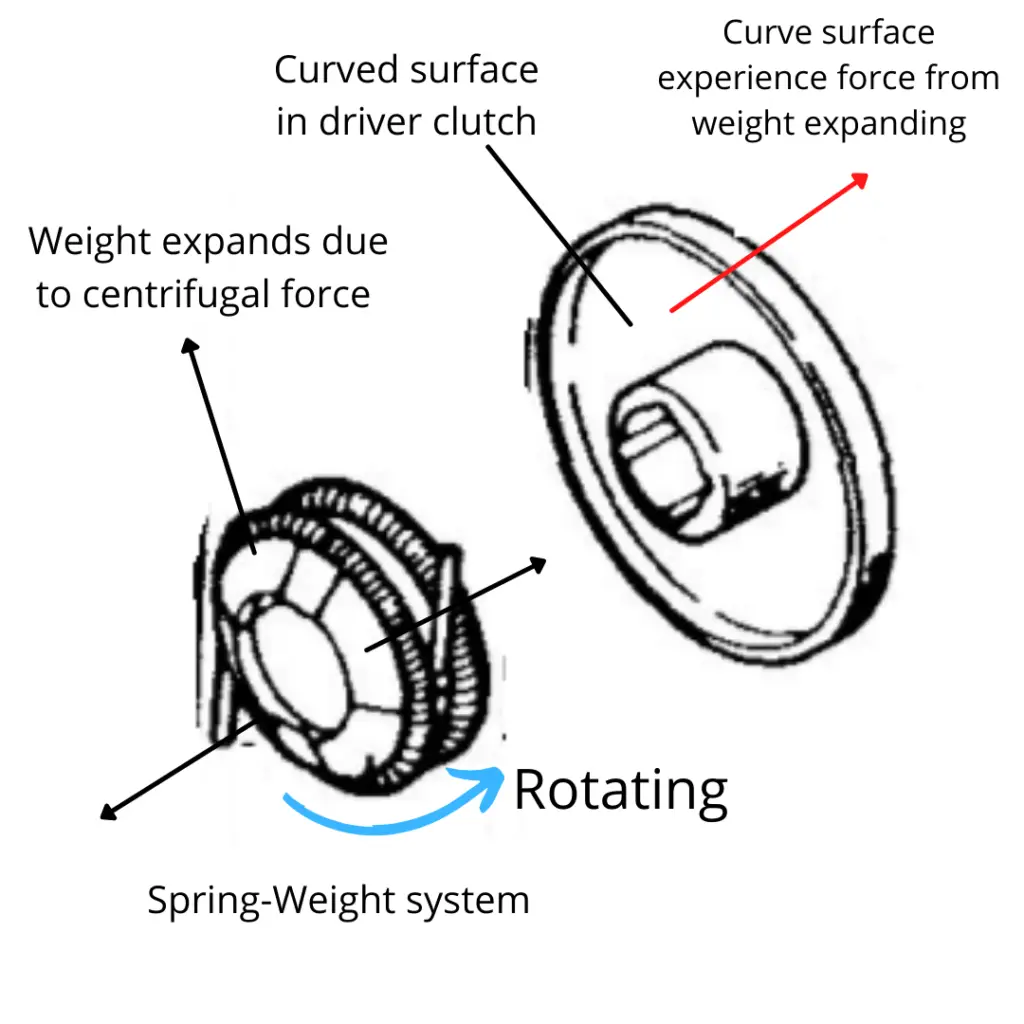

While the driver pulley is pushing the belt upwards, the belt will consequently apply a force on the movable part of the movable half of the driven pulley, if you look at the diagram, the movable half of the driven pulley has a spring that will resist the force from the belt.

Depending on the rpm of the engine, all the forces will balance out and your kart will go at some specific gear ratio.

The 4 stages diagram from their manual does a good job of explaining the relation between Engine RPM and different gear ratios the torque converter achieves.

At idle condition, there will be no engagement. As the RPM of the engine increases, the active diameter of the driver will start to increase while the driven dia decreases, giving you infinite gear ratios in between these 2 extremes.

Gear Ratios:

The torque converter will give you infinitely different gear ratios. The ratio will be higher when you are just starting out and will decrease as the engine’s RPM increases. This means it will create more torque to start with and decrease in torque with more speed, making it ideal for most situations.

Calculating the gear ratio:

The gear ratio between the 2 pulleys will change, in the Comet 30 Series, the ratio ranges from 2.7:1 to 0.9:1.

To find the gear ratio you need to know the number of teeth in the Torque converter sprocket, the wheel axle sprocket, and the jackshaft sprockets (if any).

For example, let’s say that we have the Torque convertor with a 12T sprocket and the wheel axle sprocket has 60T and no jackshaft.

In that case, the ratio between the 2 sprockets is 5:1, to find the ratio of input and output shaft we just multiply all the ratios, so in this example, the maximum ratio is 13.5:1 and the lowest ratio is 4.5:1

Spring Adjustments:

If you’re looking to get a better launch then changing the springs and weight is your go-to option, the harder springs are going to require higher rotations to engage, similarly, the lighter weights will also require more rotations to engage.

You can also change the driven pulley’s spring, and/or change the hole to which your spring is attached. We have a detailed guide on how to adjust springs. Could be a good starting point for modifications.

Conclusion

Torque Converter/CVT really are well-engineered, the different gear ratios it provides give you great mechanical advantages, no wonder that so many people prefer it over the centrifugal clutch.

A clone engine such as the predator 212 along with a torque converter is the best way to go if you have the budget and will be driving your go-kart off-road and are not too worried about the top speed. These CVTs also last a long time, check our list for the best torque converters.