30 series vs 40 series Torque Converter (Go-Karts/Minibike)

If you’ve decided to get a new torque converter for your go-kart or mini bike, you’re likely trying to decide between the 30 and 40 series. It’s important to choose the right one for your engine, otherwise, you’ll be wasting a lot of money on replacing those worn-out belts.

The 30 series is rated for 2-8hp Engines and the 40 series is for 8-18hp engines. So if you’re using an unmodified predator 212 or other honda clones with a max power of 6.5hp or lower, then 30 series is for you, if you’re using a more powerful engine such as the Predator 420 then go for the 40 series.

That’s the short answer if you were wondering which one’s for you.

But in the article, we will have an in-depth comparison of their Specifications, the difference in parts and materials, Upgrades, and then the pricing to decide whether it fits your budget. (Use the table of content to skip to the section you want)

Specs

30 Series | 40 Series | |

| Recommended Engine | 2-8hp | 8-18hp |

| Belt Type | Asymmetrical | Symmetrical |

| Belt Top Width | 3/4″ | 7/8″ |

| Drive clutch’s Engagement RPM | 2200 RPM (Can be modified) | 1600 (Can be modified) |

| Driven Unit dia | 6″ or 7″ | 7 1/2″ or 8 1/2″ |

| Speed reduction ratio at low speed | 3.13 : 1 or 2.68 : 1 (for 6″ and 7″ Driven respectively) | 2.43 : 1 or 2.83 : 1 (for 7 1/2″ and 8 1/2″ driven respectively) |

| Speed reduction ratio at high speed | 0.9 : 1 or 1.12 : 1 (for 6″ and 7″ Driven respectively) | 1 : 1 or 1.24 : 1 (for 7 1/2″ and 8 1/2″ driven respectively) |

The specs are taken from comet’s user manual (the clones are all the same and will have the same specs)

Driven unit:

The driven units can come in different diameters and you can change them to your liking to get higher or lower speed reduction ratios, do keep in mind though, if you change the diameter of the driven, you’ll also need to change the belt.

The driver units of 30 series come for both 3/4″ and 1″ crankshaft, and the 40 series comes for 7/8″ and 1″ crankshaft diameter.

Belt:

The belt in the 30 series is asymmetrical meaning one side is nearly flat while the other side has an angle to it while the 40 series belt has symmetry, both sides are equally tapered.

Driver Unit and Engagement RPM:

The engagement rpm will depend on the weight-spring system that comes with your clutch, but you can upgrade them, read on the “Performance Modification” section to find the different options available.

The speed reduction ratio is the ratio of the diameter of the belt in contact with the driver and the driven. As you increase the RPM the diameters changes check this article about how the torque converters work to understand it better.

Major Differences

In terms of appearance, the way to tell them apart is from the angle in the leaves, the 30 series will be asymmetrical and the 40 series will be symmetrical, apart from that, the 40 series will be much more heavies and have a bigger belt.

The differences in parts are stated below.

Difference in Weight-springs system in Clutch

The major difference is the type of weight-spring system they both use, the weight-spring system is inside of the driver clutch (the driver clutch is the part that goes into the crankshaft), which experiences the centrifugal force as the clutch rotates with the crankshaft.

The 40 series has rollers and the spring holding all the rollers together, the 30 series has circular weights and circular springs.

The spring and weight can be upgraded to increase or decrease the engagement rpm. For example, if you want a better take-off or do wheelies, you can do so by making the clutch engage when your engine is producing maximum torque.

We’ll look through the different weights and springs in the “Upgrades” section.

Difference in Belt:

As we already looked through in the specs, the belts are very different, the 40 series uses symmetric belt while the 30 series has an asymmetric belt.

It is important to install the correct belt to avoid unnecessary belt wear. Check this guide on belt selection.

Both 30 and 40 series belts are usually rubber materials, but the top width is more in the 40 series.

Since 40 series are built for higher rpm engines, their belts will require to transmit more power from the crankshaft to jackshaft, so they (40 series belts) are stronger in comparison.

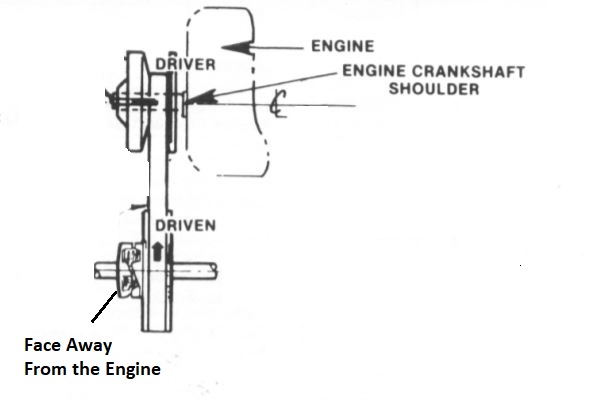

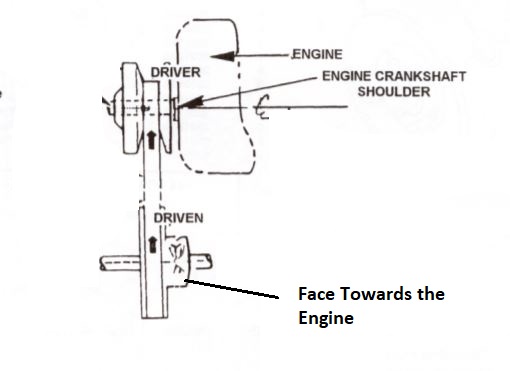

Difference in Installation:

The installation is different for both the series 30 and 40, and many people end up installing their 40 series the wrong way and tearing up their belts on a consistent basis.

The driven pulley in the 40 series that comes with a red spring in the driven will have to be installed with the driven pulley facing the engine. As shown in the diagram.

Or put in other words, the 2 movable parts of the torque converter will face each other in a 40 series Torque Converter.

We do have a more detailed guide on the installation of 30 series and 40 series that you can check out.

Performance

Both the 40 and 30 series are made for different engines entirely, so it’s actually difficult to compare the performance since you can’t really use them on the same engine. But, what if you tried to compare them in the same engine?

Can you use the 30 series in more powerful engines?

It is not recommended to do, however, many people use a cheap 30 series on an Upgraded Predator 212, which can produce as much as 12 hp power without any major issues. However, I recommend you to use a 30 series juggernaut for modified engines, they are only slightly more expensive.

Ok, that covers the small engines, what about the big blocks?

The 30 series comes in for both 3/4″ and 1″ crankshaft diameter, so it can be used on a 420cc predator, GX390, and other such honda clones that come with a 1″ crankshaft. So you can do it if you’d like to. But you’ll likely end up burning through the belt and clutch.

Why? The more powerful engine will make more torque, so the components inside the clutch and the belt itself will experience a lot more force in the bigger engine, causing more deformation. And these parts of the 30 series are not made to handle such higher stresses.

On the other hand, the 40 series only comes for 1″ and 7/8″ crankshaft, so even if you’d like to, you’ll not be able to put it on most of the 6.5hp honda clones, without modifying the crankshaft itself.

Upgrades

Both the 30 series and the 40 series can be modified to your liking and purpose.

Modification in Driven Pulley

The driven unit comes in with a spring and a cam, there are 3 types of springs that usually come for them, green, yellow, and red springs.

Basically, you make a spring stiffer to get more power out of the engine at a particular “speed reduction ratio”. You can read more about the driven upgrade in this article.

Modification in Driver Clutch

You can change the weight and spring system inside the clutch to increase/decrease the rpm at which the clutch engages with the belt.

Generally speaking, the lighter the weight, the higher rpm it will require to engage, and the stiffer the spring, the more rpm it will require to engage.

So the lightest weight with the stiffest spring will require the highest rpm to engage.

If you make the clutch engage when the engine is producing the most torque you get a good take-off and can do wheelies.

Let’s have a look at all the different combinations of springs and weights for both 30 series and 40 series along with the rpm of engagement.

30 Series : Different springs and weights

| Spring color | Zinc Weight (320 gram) | Alum-Die Cast (146.8 grams) | Mod-Alum (90 grams) |

| Black | 1400 rpm | 2100 rpm | 2300 rpm |

| Orange | 1500 | 2300 | 2500 |

| Pink | 1800 | 2800 | 3100 |

| Purple | 2000 | 3200 | 3400 |

| Blue | 2200 | 3300 | 3700 |

| White | 3100 | 4000 | 4500 |

Likely if you’re to go with the 30 series, you have a smaller engine such as the predator 212, the best spring-weight system is the one that engages at an RPM at which your engine produces maximum torque.

For example, predator 212 produces max torque at 2500 RPM. So the best combination will be 90-gram weights with orange spring.

40 series: Drive clutch engagement for different rollers and springs

| Rollers | Yellow Spring | Red Spring |

| Heavy | 1600 rpm | 2000 rpm |

| Medium | 2200 rpm | 2600 rpm |

| Light | 2400 rpm | 3100 rpm |

Similar to the 212cc engine, the 420 Predator also produces the most torque at 2500 rpm, so the red spring with medium weight will give you a good take-off.

Original vs Clone

As you might already know, the original USA-made torque converters are going to cost you double the money, so are they really worth it?

In my opinion, the clones work just as fine for most purposes, of course, the original is made of better and heavier materials but they are also 2-3 times the cost.

If budget is not the issue for you then sure, you should go ahead and buy the original Comet

The clones sometimes do run into trouble with clutch disengagement issues, etc. But if you buy a clone with high amazon ratings then you’ll be just fine. Check our buyer’s guide for the best 30 series Torque Converters.

Final Verdict

Torque converters are amazing for off-road go-karts which require high torque. Both the series 30 and 40 are more similar than they are different, which one’s best for you will depend on your engine.

If you have an engine with a max power of 2-8hp then go for 30 series and if your engine has max-power of 8-18hp then go for the 40 series.

You can modify the springs and weights in the driver and driven to change the engagement rpm for better take-off.